STARK – Innovative Coatings for Maximum Performance

Every production facility presents unique challenges and has specific requirements. At Staltec, we offer customized coating solutions precisely tailored to the operating conditions and technical specifications of your equipment. Our approach is holistic and customer-oriented, and we do not limit ourselves to a single coating process. Instead, we consider the entire range of available coating technologies to find the perfect solution for your product and specific needs.

Our experienced team works closely with you to develop a deep understanding of your production processes and the associated requirements. This intensive collaboration allows us to develop customized coating solutions that not only meet but ideally exceed your expectations. By utilizing a variety of innovative coating technologies, we ensure that each solution is optimally tailored to the individual operating conditions of your facility, delivering outstanding results.

Why STARK Coatings?

Increased Lifespan

STARK Coatings are designed to significantly extend the lifespan of your equipment and machinery. In steel production, where equipment is exposed to extreme temperatures, abrasive materials, and corrosive chemicals, our coatings provide crucial protection. They form a durable barrier that shields surfaces from wear and preserves the reliability of the equipment under harsh conditions. Wear minimization reduces the need for frequent maintenance and component replacement, leading to less downtime and increased production capacity. Components equipped with STARK Coatings maintain their functionality and efficiency over extended periods, significantly reducing lifecycle costs.

Environmental Protection

STARK Coatings makes a substantial contribution to environmental protection. The advanced materials and technologies used in our coatings are designed to reduce energy consumption and minimize the emission of pollutants into the environment. By improving the efficiency and longevity of the equipment, operations can optimize their resource use and reduce waste. This not only leads to more sustainable operations but also helps companies meet stricter environmental regulations and improve their environmental footprint.

Cost Efficiency

Investing in STARK Coatings pays off in the long run by reducing overall operating costs. Our coatings enhance the performance and reliability of equipment, resulting in reduced downtime and increased production. Lower maintenance costs and reduced downtime mean a higher return on investment (ROI) for your equipment. Additionally, further cost savings can be realized through the longer lifespan of components and improved energy efficiency. STARK Coatings are an economical solution that not only boosts operational efficiency but also helps alleviate the financial burden of expensive repairs, maintenance and downtime.

Our Product Range

STARK BASE

Basic protection against wear and corrosion for milder conditions. Ideal for general industrial applications where a robust and cost-effective solution is

required.

STARK PRO

Advanced coatings for enhanced wear and heat resistance. Designed for applications that go beyond basic requirements and require specialized performance.

STARK ECO

Sustainable coatings designed to minimize environmental impact. These eco-friendly options provide top-notch protection for your equipment.

STARK MAX

Provides extreme protection under the most demanding conditions, ideal for equipment exposed to severe wear and corrosion.

Discover the potential of STARK Coatings across various applications

Rolls and Rollers in Hot and Cold Rolling Mills:

In metal processing facilities, including those producing flat roll, structural beams, rail, specialty bar, shaped products, wire, and other metal products, the materials are subjected to extreme thermal and mechanical stress. Whether processing steel, aluminum, titanium, stainless steel, or other metals, STARK Coatings protect the roll surface from wear and deformation, increase uptime, and reduce maintenance efforts. By applying these coatings, consistent quality of rolled products is ensured, and susceptibility to production disruptions is significantly reduced.

In cold rolling mills, where metals are precisely shaped at room temperature, the quality and durability of the rolls are crucial. Traditional coatings like hard chrome or nickel plating can quickly reach their limits under these demanding conditions: they lose their surface quality and properties, resulting in frequent and costly roll changes.

STARK Coatings offer a revolutionary solution here. Our specially developed coatings not only improve the surface hardness of the rolls but also optimize their sliding properties. This leads to a significant extension of the service life of your rolls and ensures that the surface quality of the processed metals remains consistently high.

Bath Equipment in Galvanizing Plants

In galvanizing plants, bath equipment is continuously exposed to the aggressive influences of molten zinc and/or aluminum. STARK Coatings provide effective protection against the corrosive, adhesive, and abrasive effects of the molten metal, extending the lifespan of the components and minimizing operational disruptions caused by failures. Typical application areas for STARK Coatings include bearing systems, bath rollers, snout tips, and bearing arms.

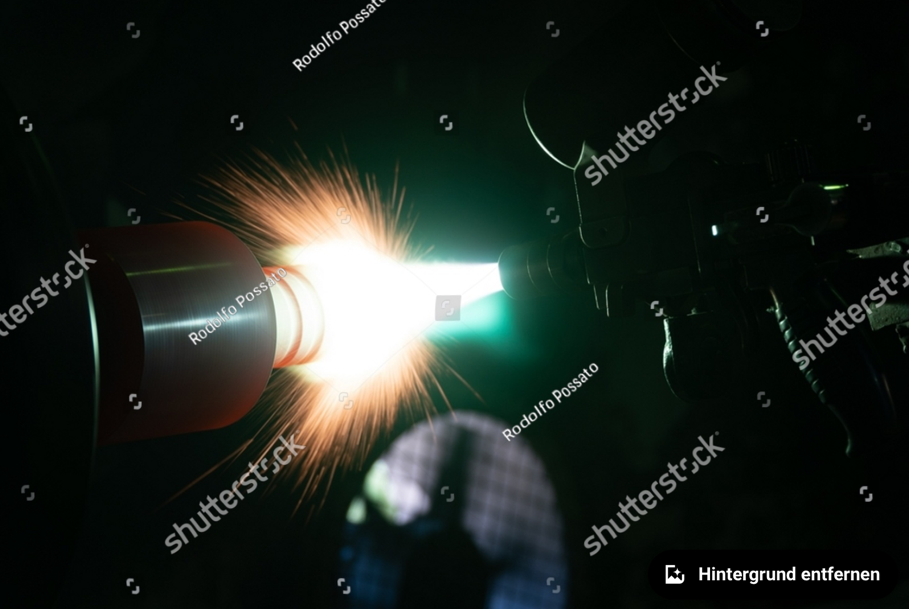

Heat Shields and Burner Nozzles

In many industrial furnace applications, such as in sinter plants, coke and blast furnaces, or forging furnaces, components like heat shields and burner nozzles are exposed to extreme temperatures and corrosive gases. STARK Coatings provide protection against oxidation and corrosion, maintaining the reliability and functionality of these critical components over a longer period.

Hydraulic and Pneumatic Components

Hydraulic and pneumatic components play a crucial role in heavy machinery and industrial plants and are often exposed to high pressures as well as corrosive liquids or vapors. Traditionally, hard chrome coatings have been used for these components to prevent wear and corrosion. However, the use of hard chrome poses significant environmental and health risks, including the release of harmful hexavalent chromium compounds.

STARK Coatings offer an advanced and environmentally friendly alternative to traditional hard chrome. These innovative coatings effectively protect hydraulic and pneumatic components from premature wear and corrosion, enhancing the overall reliability and safety of the equipment. By using STARK Coatings, companies can not only improve the performance of their equipment but also reduce their environmental footprint and ensure compliance with environmental regulations.

Learn more about the benefits of STARK Coatings and how you can increase the efficiency and longevity of your equipment. Contact us today to schedule a consultation with our coating experts or to receive more information.