BANNER Bearing Units - Bearing Solution for Molten Metal in Galvanizing Plants

Staltec’s BANNER bearings and PANTHER bushing systems are the ultimate solution for the extreme demands of continuous galvanizing lines. Designed to function precisely and reliably in molten metals under the harshest conditions, such as temperature fluctuations, wear, and corrosion, these components set new standards in terms of performance and durability.

By utilizing advanced materials and innovative manufacturing technologies, BANNER bearings withstand even the most aggressive media and stresses. Even at high line speeds and maximum loads, they guarantee smooth, vibration-free operation, ensuring consistently outstanding product quality and maximum plant availability.

Challenges and Solutions

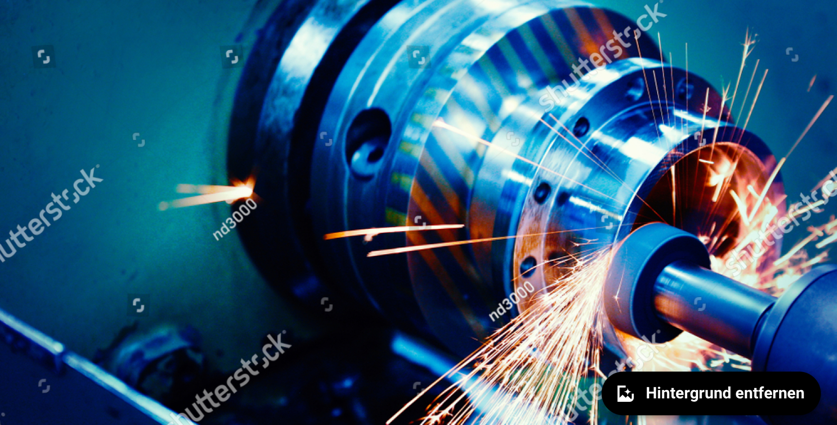

The demanding operating conditions in molten zinc baths of continuous galvanizing lines place the highest demands on the surface integrity of the bearings. High temperatures, corrosive media, and abrasive wear can drastically increase the friction between the bearings and roll journal sleeves. The result: a decline in the surface quality of the galvanized steel strip and unstable process conditions.

Conventional bearings quickly reach their limits in this environment. Often, a significant increase in the coefficient of friction is observed after just 1-2 weeks. To maintain consistently high product quality, frequent bearing changes are unavoidable, leading to costly plant downtimes.

Staltec has addressed this issue and developed a groundbreaking solution with the BANNER bearing unit. By using special high-performance materials and optimized surface topographies, BANNER bearings achieve consistently low friction over longer operating times. At the same time, they reliably withstand the aggressive environmental influences.

Inspired by Dr. Bruce Banner

The BANNER brand is inspired by the incredible strength and resilience of Dr. Bruce Banner’s alter ego. Just like him, who shows nearly unlimited strength and indestructibility under stress conditions, BANNER bearings are designed for tough conditions. Our advanced bearings withstand high temperatures, corrosion, and wear that would quickly destroy conventional materials.

Performance Features that Set New Standards:

Maximum Corrosion Protection

BANNER bearings are designed for the challenging galvanizing media. Through optimized material selection and special surface technologies, dross adhesion and corrosion phenomena are minimized. The result: significantly increased component life and consistent surface quality throughout the entire campaign cycle.

Friction-Optimized Sliding Contact

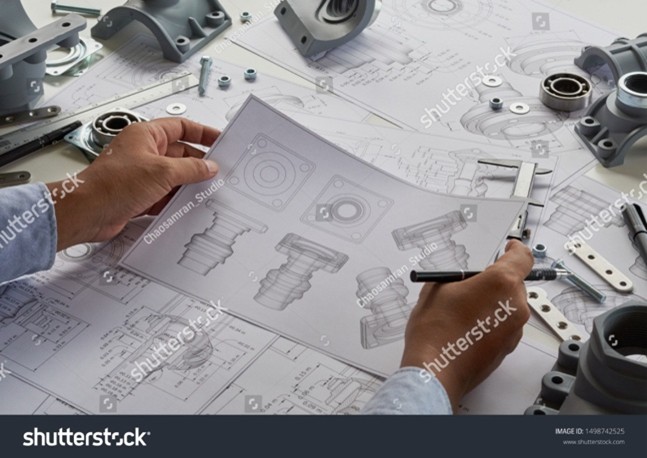

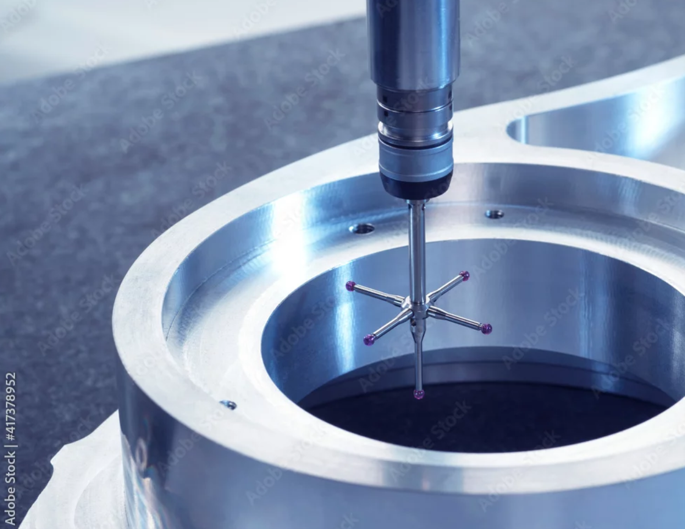

The running surfaces of BANNER bearings feature a finely tuned surface topography. Thanks to continuous development and modern manufacturing processes, we achieve consistently low roughness values in the sliding contact. This effectively minimizes friction and wear, which is essential for maximum plant efficiency.

Maintenance-Friendly Design

Every detail of the BANNER bearings is designed for easy handling. Weight-optimized modules, intuitive positioning, and zinc-repellent surfaces make installation and maintenance easier. Thanks to the thoughtful design, time-consuming assembly procedures and lengthy maintenance work can be significantly shortened.

Resource Efficiency Through Modularity and Reusability

Sustainability is deeply embedded in Staltec’s DNA. That’s why we consistently apply the principle of modularity in our bearing units. The components are designed so that after their use, we can carefully check whether the bearings can be repaired or directly reused. Even if neither is possible, we offer the recycling of the units, allowing them to re-enter the material cycle. Repair, refurbishment, and reuse are integral parts of the BANNER product philosophy - for maximum resource efficiency and a minimal ecological footprint.

Universal Compatibility

BANNER bearings are designed as technology for the zinc bath mechanics of continuous strip galvanizing lines. Whether retrofits or new installations – our bearings can be integrated into any system configuration without extensive modifications. Thanks to compatible interfaces and scalable dimensions, BANNER bearings fit all common systems of bath equipment from well-known OEM manufacturers.